Support Claim

We craft our products with universal usability in mind.

More than ten years of experience in product design and manufacturing with over 200 products sketched.

Our team’s in-depth involvement with design for manufacturing (DFM) processes allowed us to produce more than 1M units in mass production.

Our expertise lies in over 10 design disciplines. Medical equipment, consumer goods, soft goods, IoT, appliances, furniture, and transportation design.

Client endorsements

I’m impressed with their ability to deal with multiple aspects of production

Ndanji Zulu

CEO, Sports RetailWe can trust them to run with the idea without veering too far away from our vision

Survival Gear Company

President of a Survival Gear CompanyDesign Process

Less than 60 days - what it took to materialize client ideas using our five-phased design process: Research and Ideation, 3D Modeling, Mechanical Design, Technical Drawing (drafting), and Rendering.

Phase 1 (Research and Ideation)

Getting a clear take of what the client wants to create is the first step, followed by exploring considerations that will affect its form, function, and novelty. The design will then be sketched according to engineering and manufacturing standards.

Phase 2 (3D Modeling)

The client’s concept is further visualized by converting 2D sketches into 3D models, elaborating the design’s features. The design for manufacturing (DFM) process is applied in this phase to ensure the end product can go through thorough quality assurance tests done by manufacturers.

Phase 3 (Mechanical Design)

DFM standards are integrated into the 3D model to guarantee that manufacturers can support the production of all parts.

Design elements are then adjusted according to DFM qualities such as heat resistance and tolerance. Adjustments will allow prototypers to produce high-quality parts used for product runs.

Simulations are then carried out, if necessary, to verify the design’s structural integrity and other external and internal factors that will affect the product’s efficiency.

Phase 4 (Technical Drawing "Drafting")

The identification and specification of unique product pieces are enumerated right off the bat to save resources in the early stages of the design process. This allows us to analyze what portions of the product need to be customized.

The product’s external and internal components are now then drawn out, along with its sizes and dimensions. An assembly process is now then produced for the manufacturers and assembly team to follow.

This is followed by identifying the exact materials needed for each part, allowing us to estimate costs for tooling, constructing prototypes, and mass manufacture.

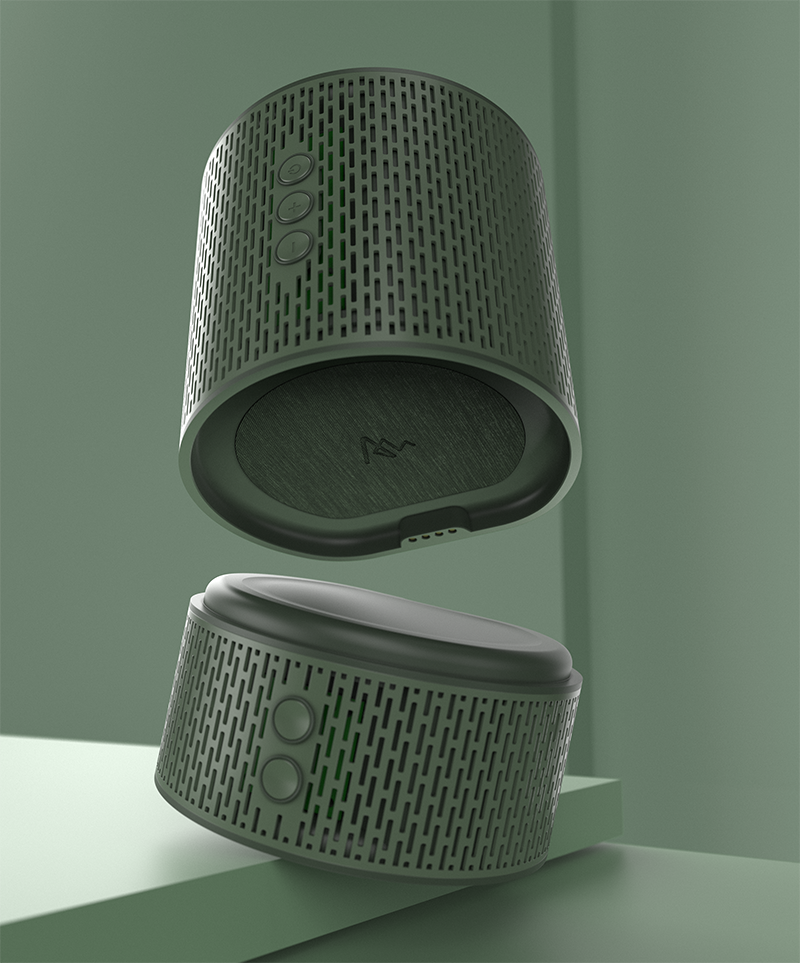

Phase 5 (Rendering)

We will be making a photorealistic rendering of the product. It will then be used for marketing and manufacturer’s guidance on its CMF (Color, Material, Finish).

The output rendered that will be used for marketing is produced on a plain background to give the best visual sense of the product’s CMF. This then can be used for eCommerce, marketing, brochures, crowdfunding, packaging, and investment decks.

Meanwhile, we will also render the product in an environment it will best fit in. A coffee maker, for example, will be rendered in a kitchen countertop or with a person using it in a static image.

Support Claim

All of this will take place as you're guided through the process.

We've partnered with newcomers and industry experts alike.

A significant number of our work have been mass-produced and generated millions of dollars in sales

You can be part of this success too.